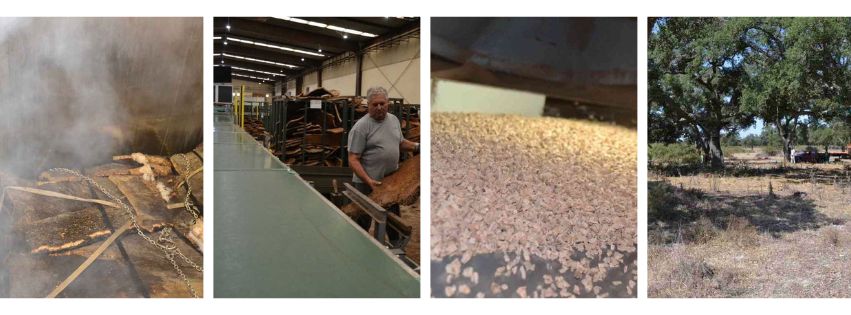

Wine is never just a beverage; for those who fall in love with it, it often serves as a medium that inspires and facilitates a journey to places that might become eternal sanctuaries of the soul. As Pessoa said, “Travel is the traveler. What we see is not what we see, but what we are.” Alentejo, a region in Portugal, Évora district, Rio Frìo Forest, property of the Amorim Group, the world’s leading cork stopper producer. Before reaching it, one traverses a sort of abandoned village with Mexican charm. Men work on the stripping of cork oak bark—there lies the privilege of the traveler, an ancestral place of wild beauty that embeds itself in the soul forever.

Because wine, in addition to being terroir, vineyard, grape, cellar, bottle, and packaging, is also a stopper. In recent years, there has been much debate about the best closure system to keep the bottle intact. Personal preferences of enologists and wineries have led them to choose one system over another: cork, screw cap, glass, plastic materials (now unsustainable), and frankly, no one has the definitive answer. The fact remains that natural, single-piece cork, being a living material like wine, maintains an undeniable allure. But how does the cork oak bark get from the tree to the bottle? The process is truly fascinating and requires a dedication to the art of patience, beginning with stripping.

Stripping

In the cork oak forests (Quercus suber – Latin) of Alentejo, an untouched place, workers harvest the bark and select the segments for cork closures. The Portuguese cork forest, known for its natural growth, stands as one of the 35 global biodiversity sanctuaries and contributes significantly to the world’s cork production each year. Portugal is the leading producer, followed by Spain and other Mediterranean countries, including Italy, which focuses its activities in Sardinia.

The cork stopper cycle begins with stripping, a process still largely carried out by hand by local teams of strippers who pass down artisanal knowledge from generation to generation. This craft is currently the most lucrative artisanal activity in the world due to the high specialization required and the limited availability of qualified personnel. This role also helps combat social desertification that would otherwise afflict these areas far from regions where industrialization or urbanization is more prominent.

Periods of stripping

Stripping operations take place between May and July, when workers can detach the bark from the trees. During this period, the sap is perfectly positioned between the plant’s trunk and its bark, making it easy to separate from the mother plant while fully respecting nature’s cycles. The strippers’ dedication is total: they use a small axe, leverage with a specific handle, and detach the cork. They perform a meticulous job to avoid harming the plant, as any cut deeper than necessary could cause damage, even death, or at least reduce productivity. Stripping also benefits the plant, akin to shearing a sheep, as it prevents the accumulation of cork on the outside, avoiding insulating effects and allowing the plant to regenerate more balanced.

From the birth of an oak tree to the first stripping takes 25 years. The initial bark removal does not serve for cork production because it remains immature and unsuitable for quality production. Afterward, another 9 years pass for a second stripping, and an additional 9 years elapse before producing corks. In practice, it takes a minimum of 43 to 45 years from the plant’s birth to start producing cork stoppers. The average lifespan of a cork oak is around 200 years.

In counteraction to climate desertification, in an era where trees struggle to find fertile ground for natural growth typical of cork forests, Amorim has acquired 8,700 new hectares of historic forests to protect them and, after thorough study, has embarked on planting over 1.5 million cork oaks, adding to those already present naturally. Furthermore, for several years now, the company has ensured healthier and faster growth for its cork oaks with an innovative drip irrigation system, optimizing water resources that are increasingly at risk.

Stacking at Amorim Headquarters

Workers immediately transport the harvested cork to the nearest Amorim facility. Each piece is stacked with the outer side facing up and the inner side down. They place the stacks on draining concrete surfaces with a special cover, allowing for healthy and slow drying over about six months. This process prevents the cork from rotting and developing other defects, such as yellow stains responsible for damp cardboard aromas, which could later transfer to the cork and alter the wine.

Amorim’s four preventive measures against potential cork defects are:

- Draining concrete floors to prevent contact with the ground (previously, cork was left to season in the forest, leading to contamination and stagnation issues).

- Cutting the wedge: removing the part that has been in contact with the ground for years and is potentially more polluted.

- Covering stacks to prevent yellow stains or rotten cork—damp cardboard-like aromas—due to water and/or moisture stagnation during drying.

- Raising stacks off the ground to allow better air circulation and avoid contact with the floor of each plank.

Treatments

After 6 months, the planks undergo two preventive and curative measures: boiling and vaporization.

Boiling

For boiling, the cork planks are placed in pressure-free containers at 98°C for a 60-minute sanitization cycle, repeated in five cycles. Introduced by Amorim in 2009, this method flattens and thickens the bark while reducing TCA incidence by 40%. It eliminates most microorganisms and impurities by making them volatile through the high temperatures of the water. The water, being a primary resource, is continuously cleaned and filtered for reuse. This process maintains its cleansing properties and minimizes waste through continuous circulation for 72 hours in winter and 48 hours in summer.

Vaporization

After boiling comes vaporization with alternating wet and dry steam at 135°C—a particularly delicate process because the steam must be carefully managed. Its gaseous nature allows deeper cleaning, serving almost exclusively as a curative measure.

After drying, the planks are analyzed and sorted based on thickness and “purity,” and those with visible defects are discarded. The actual cork production begins: on one side, die-cutting, the production of single-piece corks, which are used for the most prestigious bottles and are essential for wines intended for medium to long aging; on the other side, the production of “technical” corks, made from ground cork reassembled, for wines typically consumed within two or three years.

At the end of this long process, the corks are washed, lubricated, and branded with food-grade inks or burned by the specific requirements of individual wineries. There is extensive customization available in terms of graphic decorations, practicality, and design to ensure technical quality. Notably, and in this case, sustainability is not just a marketing term but part of Amorim’s genuine environmental sensitivity.Extracting one ton of cork from the oak captures 73 tons of CO2 from the atmosphere, making this process the most sustainable industry in the world.

Amorim’s World of Projects

Amorim’s obsession with research drives the company to lead the global technology front, resulting in the production of the safest cork stoppers on the market. In this regard, readers interested should delve into the company’s four cutting-edge technologies: Naturity, ND-Tech®, Xpür®, Cork Nova®.

Despite being a profit-driven company, Amorim operates within a realistic and tangible social framework. The Amorim Group has been preparing a sustainability report since 2006. The Italian branch started working in this direction with the ETICO project, launched in 2011 to recover used corks through support from NGOs that collect them and receive financial contributions to fund their projects. A virtuous circle that begins and ends with nature, in its best form: reuse. Each year, Italy used to discard 800 million corks. Today, ETICO has successfully recovered and repurposed over 400 tons of used corks. Since the project began, we have donated more than €400,000 to fund NGO projects, thanks to cork sales and Amorim Cork Italia’s voluntary contributions. This initiative not only helps the environment but also significantly supports social causes. Additionally, ETICO gave rise eight years ago to the Eticork initiative, in collaboration with Vinibuoni d’Italia, which introduced recognition for wineries that adopt virtuous practices in their daily activities for the community.

The territory

The territory is another focal point of Amorim’s initiatives, with a series of collaborations with local higher education institutions where the company is based, as well as university courses. Amorim has also supported and promoted various initiatives throughout its history. For instance, it has supported Terra Fertile, a project linked to food sustainability, which involves providing fresh, local, and organic fruit to the company, with deliveries made directly by individuals with disabilities (regularly, three times a week). Another systematic collaboration is with the local branch of AIPD, the Italian Association for People with Down Syndrome. Additionally, in partnership with other organizations, Amorim has established a support center for women victims of violence in the municipalities of Conegliano and Vittorio Veneto.

People

Concern for people has always been a key element of Amorim’s identity, starting from within the company through innovative work-life balance measures. Amorim Cork Italia was one of the first Italian companies to receive the Family Audit certification, a management tool designed to create innovative human resource policies focused on the well-being of employees and their families, work-life balance, and business growth. Another project is the AMORIM CORK ITALIA ACADEMY, established during the pandemic, aimed at providing employees with a range of skills and maintaining focus on their daily needs. The flagship project offers free, personalized health check-ups through an agreement with a leading local healthcare provider. Regarding work life, the company has decided to encourage employees to use more sustainable transportation by purchasing 17 bicycles available for short trips during lunch breaks to the four locations where employees can enjoy lunch provided by Amorim (a cafeteria, a restaurant, a café, and a pizzeria). The coffee break area also offers fresh fruit daily, provided by Terra Fertile, the local nonprofit previously mentioned, to promote food sustainability.

Next step: a positive Organization

The next goal is to become a Positive Organization, through a management style that fosters a corporate culture based on gratitude and employees’ fulfillment. Among the main objectives are creating a proactive atmosphere and promoting a culture of continuous growth and development within the company. Amorim Cork Italia has thus developed a new model of both company and circular economy, starting with a cork stopper.

Quinta Da Taboadella 1255

The Amorim family, dedicated to preserving the wine in their bottles and working in one of the world’s most renowned wine regions, naturally became producers of Bacchus’s nectar. The Amorim family owns 127 hectares in the Dão and Douro regions, where they cultivate exclusively indigenous grape varieties. In addition to the iconic Quinta Nova de Nossa Senhora do Carmo estate in the Douro Valley, they also own the equally stunning Quinta Da Taboadella in the Dão.

It’s origins

The first records of Taboadella date back to 1255, but its origins trace back to the 1st century when it hosted a Roman villa consisting of a house, a cellar, and a barn, along with other small structures hidden in a forest of pines, oaks, and chestnuts. This “Silvã,” or forest in Latin, corresponds to the name of the present parish – Silvã de Cima – and testifies to the ancient origins of this agricultural community.

Taboadella is located in the heart of the Dão Region, in Silvã de Cima, within the Castendo subregion. The estate covers 42 hectares between Vale do Pereiro and Vale do Sequeiro, at elevations of 400-530 meters. Portuguese architect Carlos Castanheira designed the 2500-square-meter winery using natural materials like wood and cork, blending perfectly with the surroundings. The building maintains a balance between light and shadow, allowing natural sunlight to create the ideal environment and temperature.

Taboadella is also the first winery in the Dão region to receive the prestigious Relais & Châteaux label, thanks to the inclusion of Casa Villae 1255 on the property. Casa Villae 1255 is a 720-square-meter residence featuring eight rooms with views of the Serra da Estrela slopes.

Wines of Quinta Taboadella 1255

Taboadella Caementa Rosé Caementa 2022

Made from 100% Tinta Roriz grapes, this rosé ferments and ages in NicoVelo cement tulip-shaped tanks. It is an elegant, vibrant rosé with beautiful acidity. However, it may lack that final touch of brilliance that would make it truly memorable.

Taboadella Encruzado Reserva White 2022

Made from 100% Encruzado grapes (also known as Salgueirinho), winemakers age this wine for 7 months, using 40% in used 500L French oak barrels, 30% in concrete tanks, and 30% in stainless steel vats. It is a white wine of great substance, featuring delicate fruit, a full palate, and beautiful acidity and persistence.

Taboadella Alfrocheiro Reserva 2020

Made from 100% Alfrocheiro grapes, this wine is aged for 20% in new 500L French oak barrels and 80% in second-use barriques for 9 months. The Alfrocheiro variety first emerged in Portugal, particularly in the Dão region, following the phylloxera epidemic, where it found its ideal terroir. The nose reveals notes of small red fruits and delicate spices. On the palate, it shows rare elegance and balance, with silky tannins and a memorable finish. A truly wonderful discovery.

Taboadella Jaen Reserva 2020

This wine, made from 100% Jaen grapes, ages 20% in new 500-liter French oak barrels and 80% in second-use barriques for 9 months. The Jaen grape reveals a connection to the Iberian Peninsula, as Jaen is essentially the same as the Mencia variety. Like the Alfrocheiro, Jaen is a wine that is still to be fully discovered. On the nose, it presents aromas of berries and thyme. On the palate, the tannins are refined, and it needs a bit more time to fully show its best form. Nonetheless, it is an extremely drinkable red wine.

Taboadella Touriga Nacional Reserva 2020

Crafted from 100% Touriga Nacional grapes, an iconic Portuguese variety originally from the Dão region, this wine ages for 9 months with 20% in new 500-liter French oak barrels and 80% in second-use barriques. The nose is intense, showcasing red fruits, violet notes, and spices. On the palate, it is enveloping and possesses great aging potential.

Carlos Veloso Dos Santos, CEO of Amorim Italia, discusses the environmental benefits of cork extraction.

Cork stripping at Amorim’s estate in Rio Frìo

Not only wine, but with wine comes oblivion, towards the cup: I will be glad, for fate is unaware. Who, remembering or predicting, would have smiled? From the brutish, not life, but the soul, we acquire, thinking; gathered in the intangible fate that neither hopes nor remembers. With mortal hand, I lift to the mortal mouth in a fragile cup the fleeting wine, eyes dimmed to see no more.

(F. Pessoa, Selected Poems, edited by L. Panarese, introduction by M. Breda, Florence, Passigli, 2006)

And I see people, and there’s work, and there’s always wind on the street waiting for us, as we are here to see and walk, and in our journey and desire to remember, and touch, and walk, in this restlessness, we forget positions, routes, and names, and we are small, amazed, solitary travelers, and all this wind around us is actually Lusitania.

(Ivano Fossati – Discanto 1990)

For more information, visit www.amorimcorkitalia.com